How we evaluate and validate automation before deploying it onsite

Intro Call

We have an online meeting to understand your challenge, your parts and requirements. You understand where we can perform and we decide if we build a use-case analysis.

Use-Case

Changeover times, Variants, Tolerances: We answer the question if our solution is technically and economically viable for your operation is together.

Virtual Simulation

Test feasibility before touching the floor: We simulate your process digitally to confirm if our model can work accurately and establish levels of confidence.

Deployment

Once confirmed, we deploy on-site. You get real-time performance, continuous monitoring, and adaptation to new parts.

Support

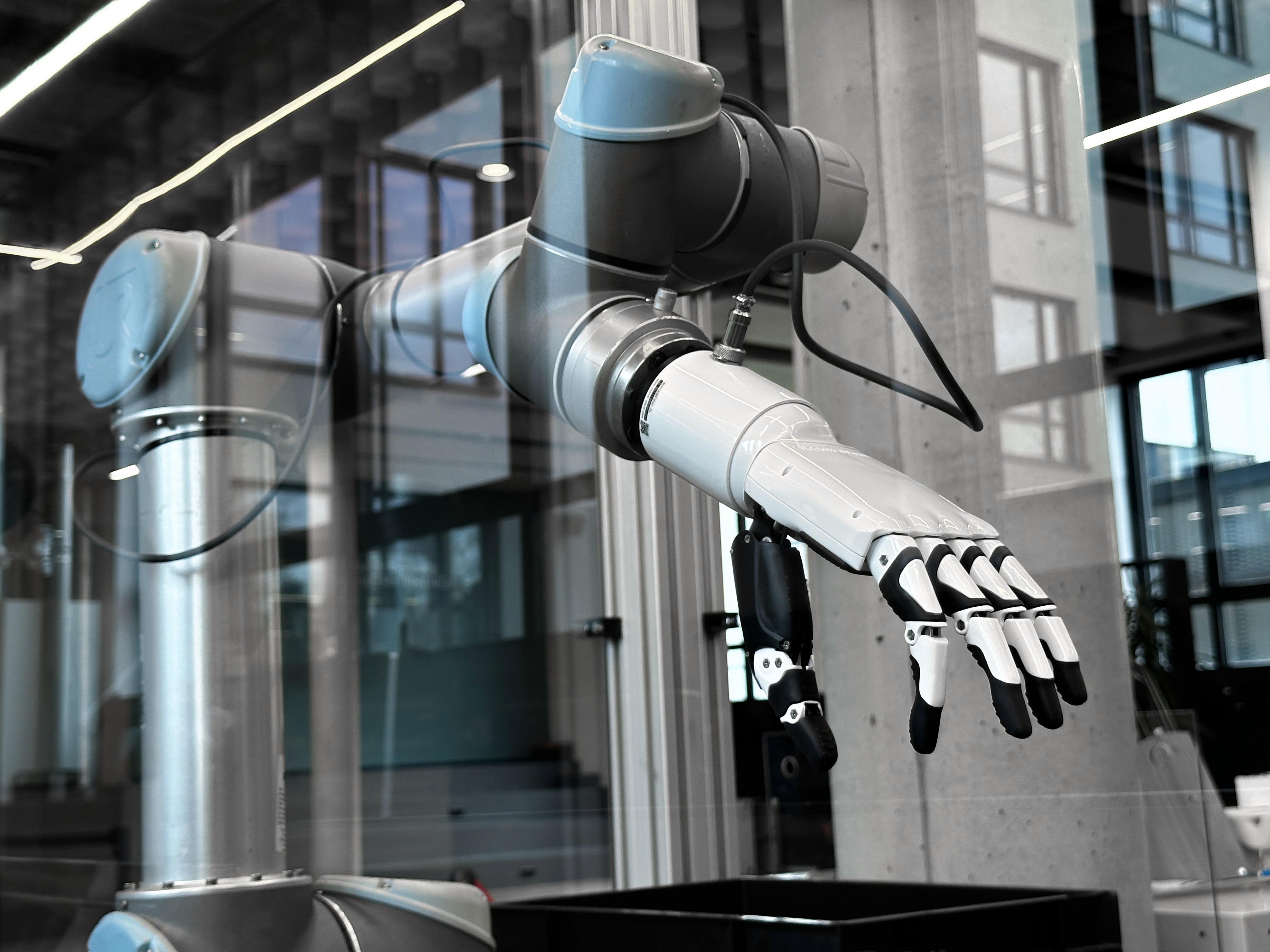

From updates to system tuning, we stick with you after deployment. Our team ensures your new robotic worker performs.

Technical and operational considerations for deploying Prehensio in production.