Our Vision is to power the world’s most capable industrial robotic operations in high-mix manufacturing.

We achieve this by delivering production-ready robotic systems that combine proven industrial hardware with a software layer designed to absorb variation, reduce deployment effort, and scale across real production environments.

Prehensio didn’t start as a company idea. It started as a recurring problem observed in applied research and industrial projects. Again and again, automation systems performed well in controlled setups, then struggled the moment real variability appeared on the factory floor.

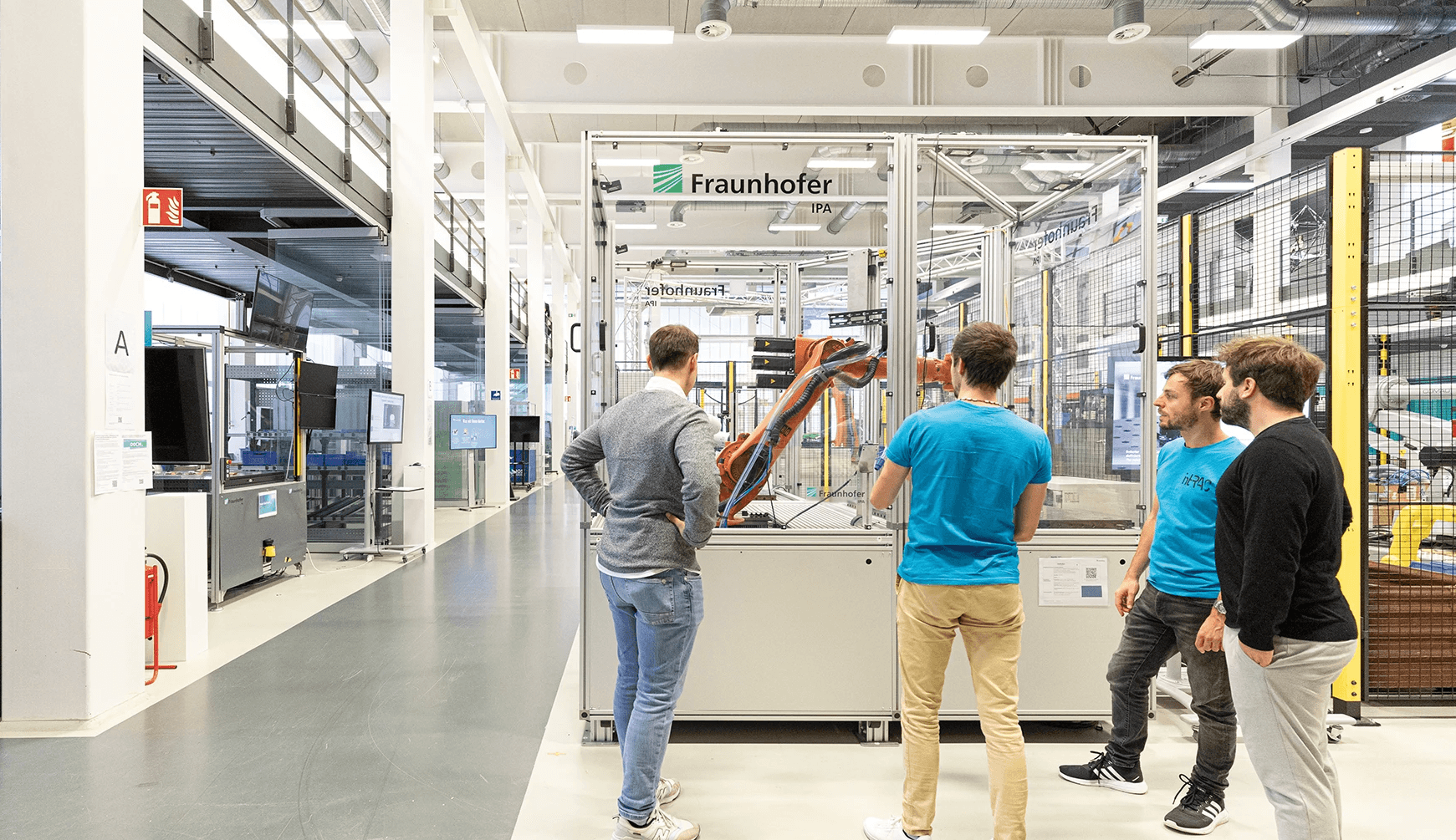

The work behind Prehensio emerged within applied robotics research at Fraunhofer IPA and later through the Fraunhofer Heilbronn Research and Innovation Centers HNFIZ. These environments exposed a consistent gap between academic solutions, traditional automation, and the realities of production.

Prehensio was founded in January 2026 to close that gap. The focus shifted from building better demos to building software that holds up under uncertainty. Software that understands contact, force, and variation, and adapts continuously instead of failing silently.

What began as research became a company once it was clear that this capability was not incremental improvement, but a missing layer in industrial automation.

We validate our systems directly with manufacturers on real parts and processes, refining them based on factory feedback. Deployment is done in close collaboration to ensure smooth integration into existing workflows.

The result is production-ready automation designed for high-mix manufacturing.

Robots fail in production not because they lack precision, but because reality refuses to stay fixed. Parts move, forces vary, assumptions break. Prehensio exists to close that gap.

We build the software layer that lets industrial robots operate under real conditions - where contact matters, uncertainty is normal, and stability must be earned, not assumed. This is not about demos or scripted motion. It is about systems that hold up on the factory floor, shift after shift.

We are looking for people who want to work on problems that are hard, physical, and consequential. If you care more about making things work in the real world than making them look impressive on slides, you will fit in here.

Join us to build robotic systems that operate where others stop.

Technical and operational considerations for deploying Prehensio in production.